Stainless Steel {1872}

While a stainless steel alloy was patented in 1872 it was not commercialized until being 'invented again' in 1912. The even tougher Maraging steel including its stainless version was not developed until the late 1950s. Maraging

Prior to 1912 silverware was pretty much just that, silver, or it rusted. Forks became much more popular in stainless since they were especially hard to keep rust free.

Tags:

Replies to This Discussion

-

Permalink Reply by Captain on June 15, 2017 at 3:32pm

-

Aluminum {1888} History

While aluminum was identified in 1782 but was often considered more precious than gold until a foundry was set up in 1888.

-

-

Permalink Reply by Captain on July 13, 2017 at 2:02pm

-

Titanium {1910} History

Titanium was first recognized in 1791 but not successfully processed into a pure form until 1910 then in any quantity until 1925. Even the most modern titanium processing is expensive, dangerous, and improbable looking.

-

-

Permalink Reply by P. Aloysius Regnad on March 13, 2023 at 5:55pm

-

As of this posting, items made from titanium are becoming less expensive, and more readily available. I have a number of tools, a small flashlight, a canteen/cookware set, cup, and eating utensils (for camping, or 'emergencies'), and some general odds and ends (like keyrings) made of titanium. They cost a bit more than they would if made from other metals, but they're noticeably lighter than steel, and stronger than aluminum for their size/thickness, highly resistant to corrosion as well as being paramagnetic (no noticeable attraction to magnets, the same as aluminum), so I think they're worth the price. Some of these items are made in the USA, and some come from China. So these days, titanium isn't just for military, government, or aerospace uses.

And it's just cool to be able to say "I have a titanium *whatever*".

-

-

Permalink Reply by Captain on November 16, 2017 at 1:17pm

-

First discovered in 1801 but not isolated into a usable form until the 1860s. Alloyed with steels it both increases ductile strength and reduces weight. Helps make superior gears and was used by Henry Ford in his early Model T chassis which is one of the reasons that so many Model Ts are still roadworthy a century later.

-

-

Permalink Reply by P. Aloysius Regnad on October 30, 2020 at 3:09am

-

Vanadium steel was also used for the connecting rods in the T1 series of locomotives.

These also incorporated a poppet valve design, which enabled them to run at higher speeds than anything else then on the rails. Speeds of 120MPH were documented, and up to 140MPH were claimed. Unfortunately, operation at speeds above 100MPH could, and did, cause damage to the poppet valves, and T1s would often have to limp into a station at reduced speed, and get sent to the repair yard. The power of these locomotives could easily induce wheel slip that caused them to overrun their specified speed limit, and create the same kind of valve damage. Rather than find a solution to these issues, The Pennsylvania Railroad decided to replace them with diesels.

These also incorporated a poppet valve design, which enabled them to run at higher speeds than anything else then on the rails. Speeds of 120MPH were documented, and up to 140MPH were claimed. Unfortunately, operation at speeds above 100MPH could, and did, cause damage to the poppet valves, and T1s would often have to limp into a station at reduced speed, and get sent to the repair yard. The power of these locomotives could easily induce wheel slip that caused them to overrun their specified speed limit, and create the same kind of valve damage. Rather than find a solution to these issues, The Pennsylvania Railroad decided to replace them with diesels. -

-

Permalink Reply by Captain on November 17, 2017 at 4:49pm

-

There is a legend that 14th century Japanese swordsmiths intended to add molybdenum to their blades making them lighter and much tougher. The secret was either lost shortly or the fortuitous accident was not repeated in later Japanese swords.

Although Molybdenum was officially identified in the 18th century its value in steel alloys was not appreciated until WW I where is allowed the production of superior armor plating and Krupp Steel's infamous super howitzer known as Big Bertha.

Molybdenum could have advanced steam age technology significantly if it had only been tried decades earlier. It is still a fairly common addition to stainless steels sometimes referred to as Chrome-Moly.

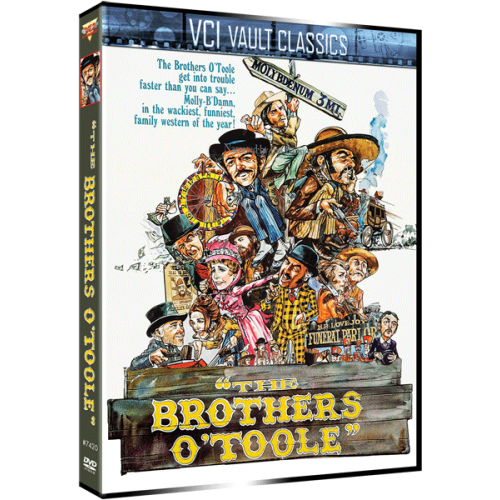

You might want to look this old movie up for more.

-

© 2026 Created by Alexander Baker.

Powered by

![]()